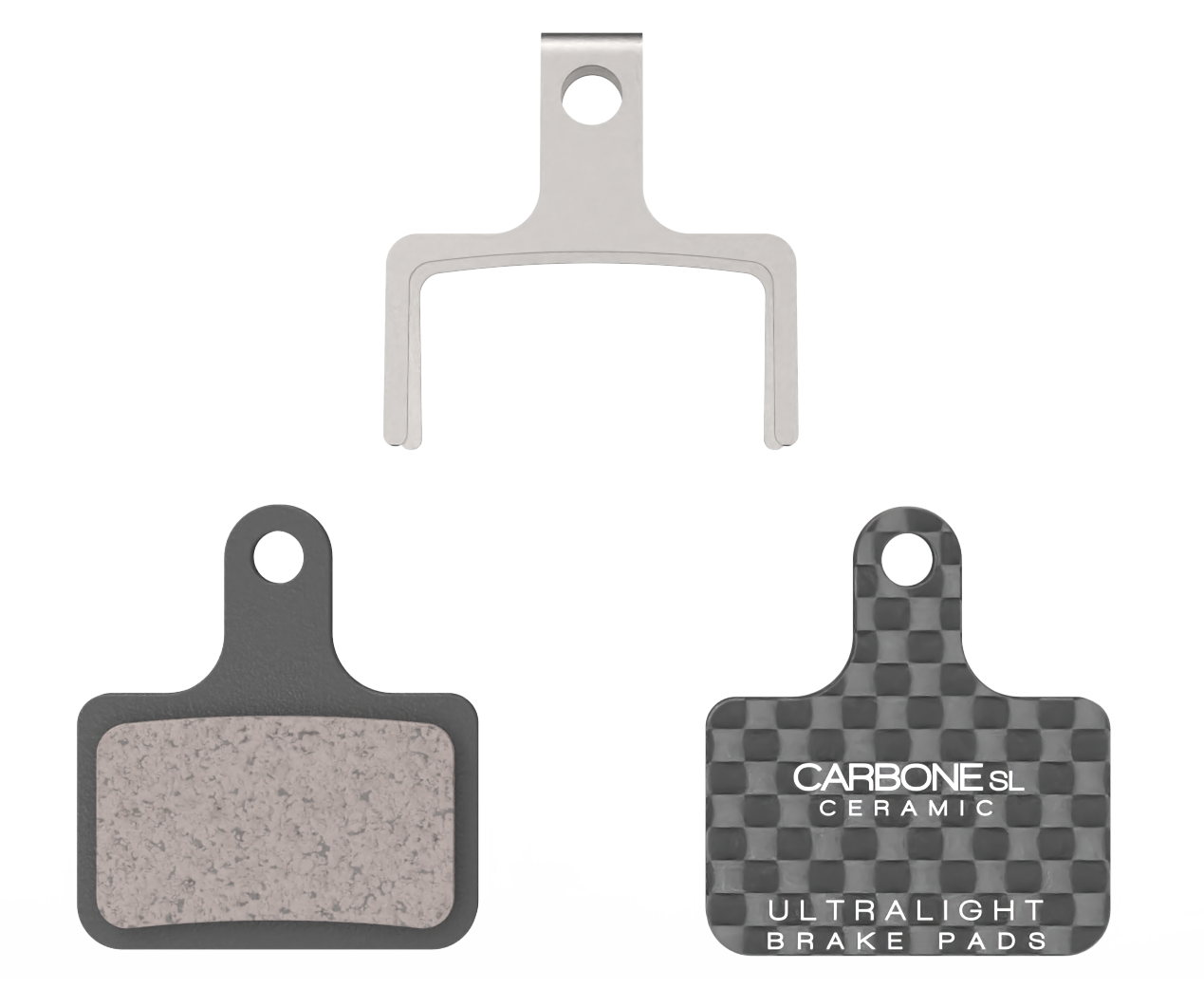

AMP’s original product was the Carbone brake pads, which use a full carbon fiber backing plate to provide the ultimate thermal shielding and vibration reduction. They claim the carbon fiber has 38x lower heat conductivity than steel and 280x lower than aluminum, the two materials most commonly used for disc brake pads. The result is that they run cooler and won’t dump braking heat into the pistons, then calipers, then fluid.

The Carbone pads come in at 13.7g, but the new AMP Carbone SL chop that to 8.8g for Dura-Ace/Ultegra brake pads, including the spring. SRAM brakes are just a hair heavier at 9.7g, all of which is much lighter than the 17g stock Shimano pads with the cooling fins.

The Carbone SL versions use a carbon-backed alloy backplate design, yet AMP says these provide similar heat reduction as the full carbon ones. They’re offered in limited quantities and fit Shimano DA/Ultegra and 2020 and newer SRAM road brakes, and come with their Ceramic pad material, which is designed for high intensity, long duration braking power. MSRP is €45 per wheel.

AMP Podium disc brake pads

Coming in much less expensive are the all-new AMP Podium brake pads, which range from €15-35 depending on brake model and pad material. Choose from Organic or Metallic (Sintered) and they have options for Shimano, SRAM, Formula, Hope, Hayes, and Magura.

Aimed at the broader trail and gravity market, they’re offered in 2- and 4-piston models (some of which also fit Shimano road brakes) and use a ceramic-coated steel back plate.

Why not carbon? They say that extremely steep terrain where you’re moving slower and braking harder doesn’t allow enough air flow to move the heat off the pads, and since it’s not going into the carbon, it just didn’t make sense here.

AMP says the WinShield Ceramic Coating still reduces the amount of heat moving into the caliper 5-10% more than traditional brake pads will – enough to keep the system in equilibrium but still provide better braking performance.